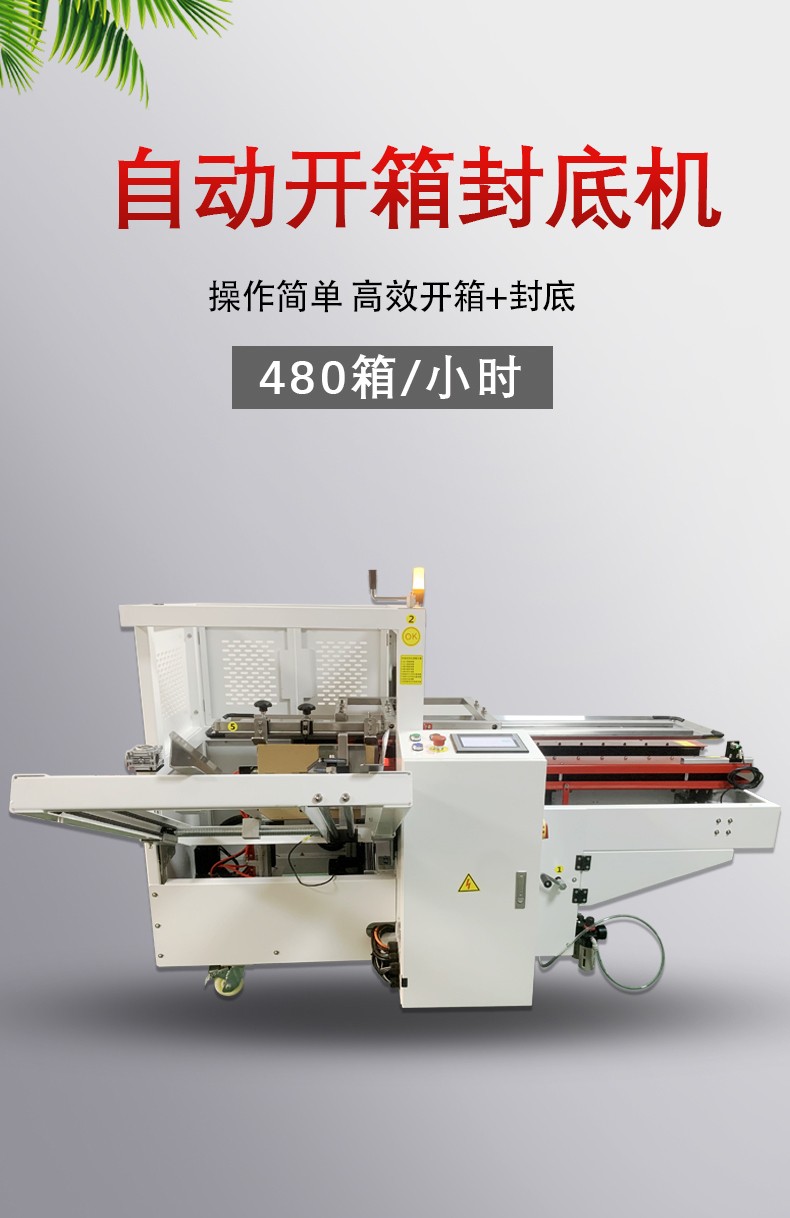

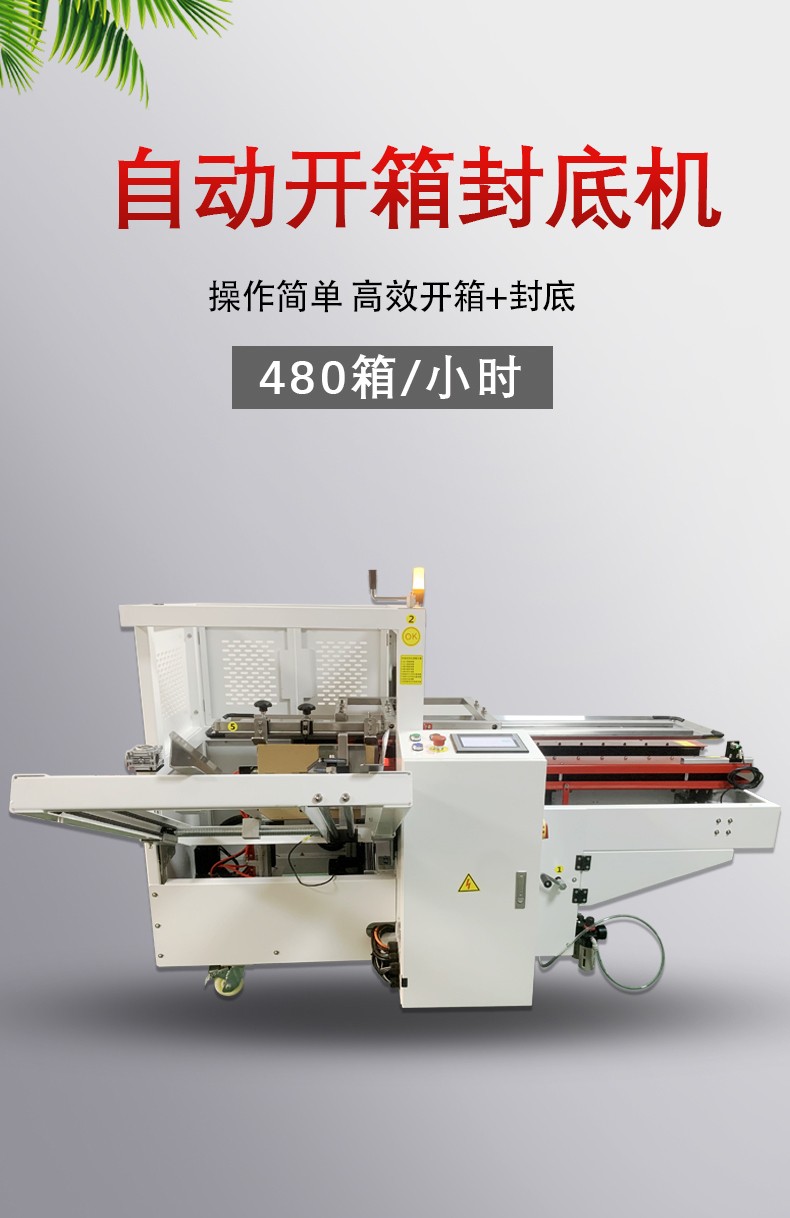

Full-Automatic Case Unpacking Machine High-Speed Vertical Case Unpacking, Flap-Folding and E-Commerce Logistics Case Unpacking and Bottom Sealing MachineSealing Machine

The carton blank is sucked out from the material storage slot by a suction cup. While being sucked and pulled out, the carton is formed. Then the front, rear, left and right flaps are folded, and finally the bottom sealing is completed with adhesive tape or hot melt adhesive. The entire process is controlled by a PLC and a touch screen, which can automatically complete packaging procedures such as carton sucking, carton opening, forming, bottom folding and bottom sealing.

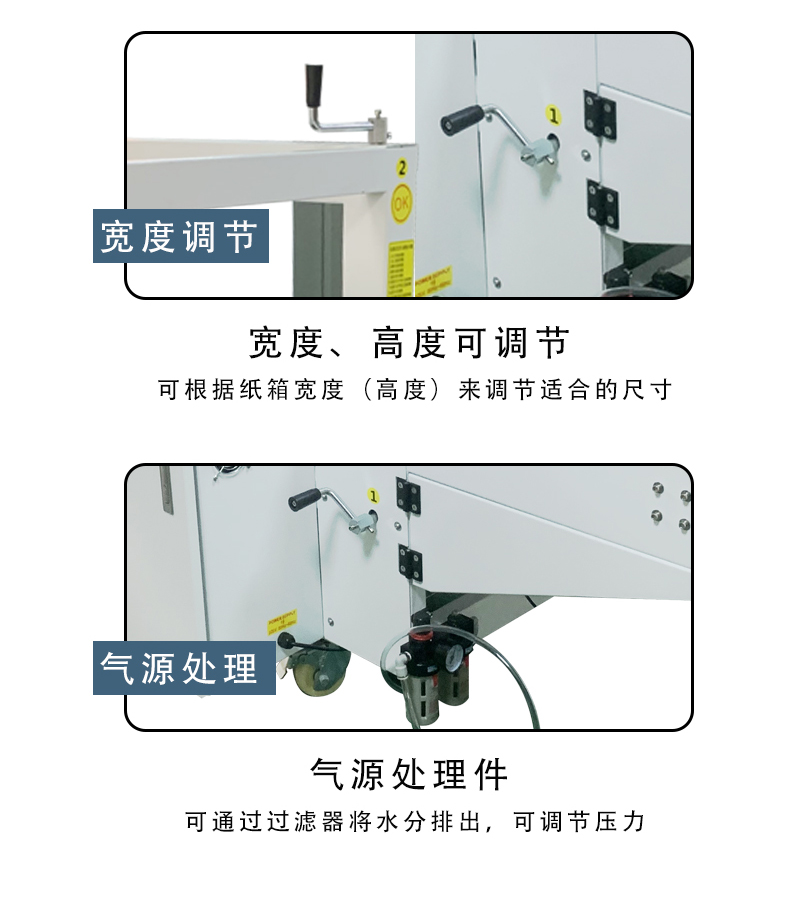

It is mainly composed of a carton feeding mechanism, a main frame, a vacuum carton sucker, a main transmission, a carton blank lifting mechanism, a rocker arm carton conveying mechanism, a carton opening mechanism, a height adjustment mechanism, a carton short-side folding mechanism, a carton long-side closing and shaping mechanism, a carton pushing fork, a carton guide rail, a compaction striker, a hot melt adhesive system, a pneumatic control system and an electrical control system.

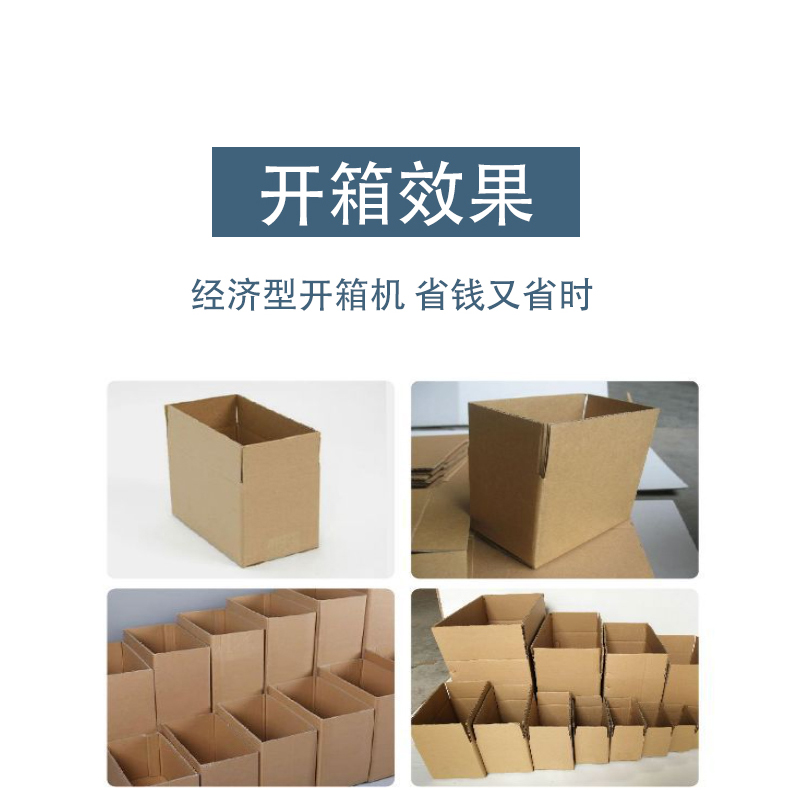

- High Efficiency and Automation: It can quickly complete a series of actions such as carton opening, bottom folding and bottom sealing. For example, Aoyu AY-4540 carton opener can open 10-12 cartons per minute, which is several times the efficiency of manual carton sealing. Moreover, it can be used with automatic packaging lines to improve the overall production efficiency.

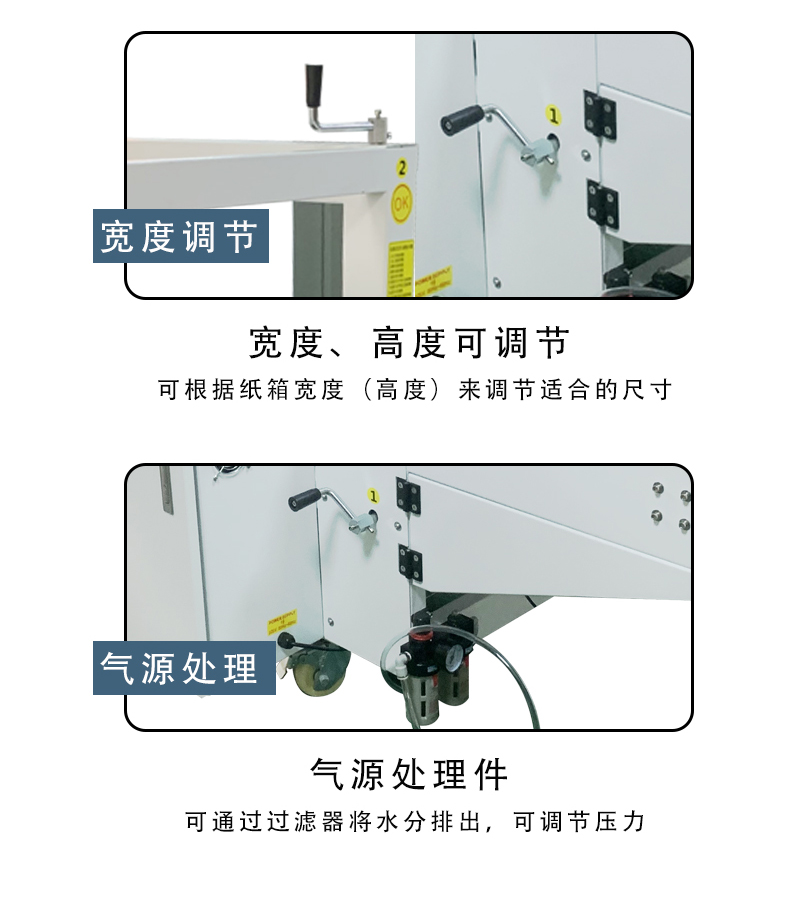

- Easy Operation: Controlled by a PLC and a display screen, operators can easily set parameters such as carton size and carton sealing speed through the touch screen. The equipment also has functions such as early warning for material shortage and automatic shutdown when there is no material, facilitating operation and management.

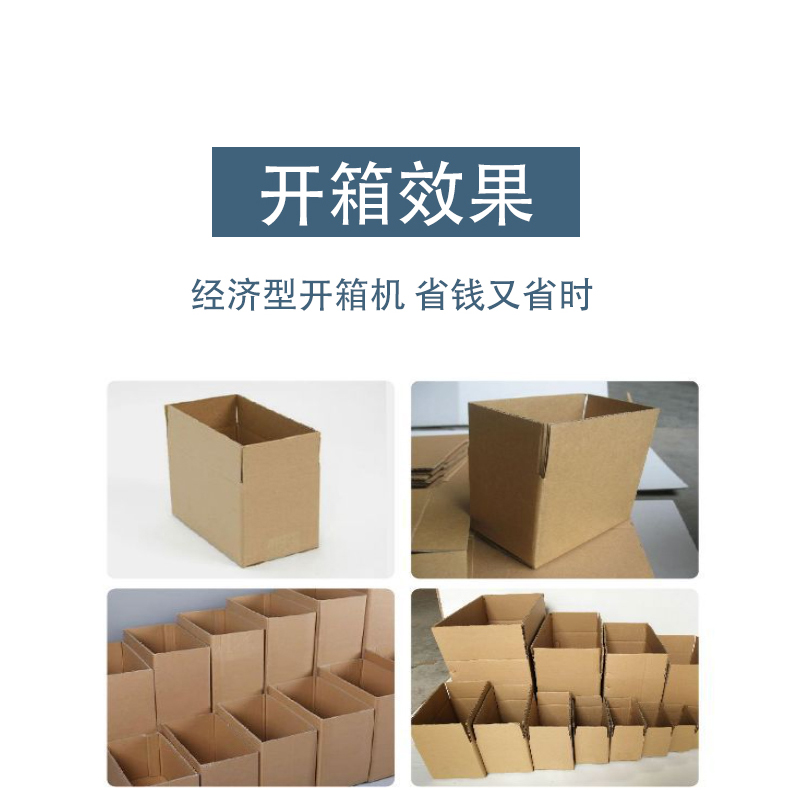

- Wide Application Range: It can adapt to cartons of various sizes. If it is necessary to change the carton specification, manual adjustment is only needed, and the required time is short, usually 1-2 minutes, which can meet the packaging needs of different products.

- Good Carton Sealing Quality: With professional and precise design, the whole machine adopts a cam continuous system, which operates accurately and stably. The carton sealing is tight, the adhesive tape smoothing effect is good, and there is no tape skipping. If hot melt adhesive is used for bottom sealing, a good bonding effect can also be ensured.

- Safety and Reliability: It is equipped with safety facilities such as a blade protection device to avoid accidental injury during operation. At the same time, the machine parts have precise performance and are durable, with a tight structural design, no vibration during operation, stable operation and a long service life.

It is widely used in food, medicine, beverage, tobacco, daily chemical, toy, electronics and other industries, and can be used for carton packaging of various products. For example, biscuits and beverages in the food industry, medicines and medical devices in the pharmaceutical industry, and electronic products in the electronics industry. It is an indispensable assembly line equipment for large-scale automated production.